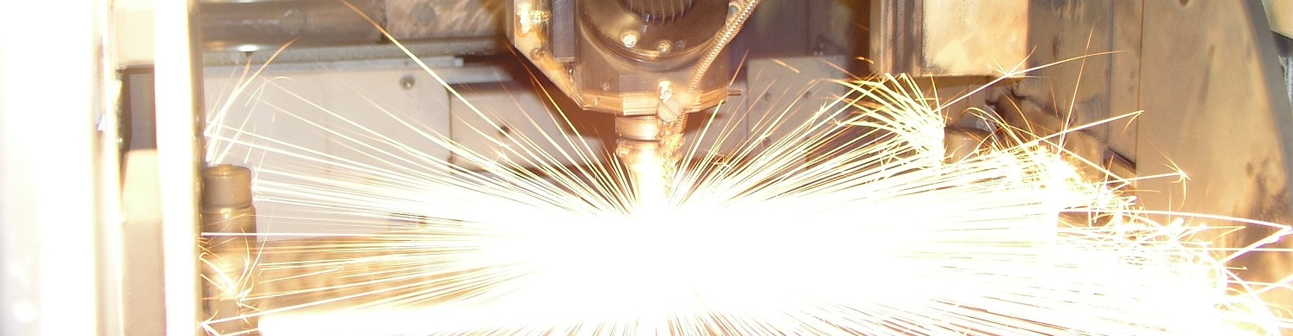

Laser Cutting 3-Dimensional

- 2-Mazak 3D FABRI GEAR 300s 4.0 KW resonator. Work piece – lengths from 78” to 315”, max 11¾” round and 8.0” x 10.0” rectangular tubular sections.

- 1-Mazak 3D FABRI GEAR 150, 4.0 KW resonator. Work piece – lengths from 78” to 315”, max 6” round and 6.0” square tubular sections.

- 1-Mazak U44 Super Turbo 3D, 2.5 KW resonator. Work piece – flat 49.2” x 49.2” x ¾” thick, tubing up to 6.125” round and 4” square, and 3-D components that fit inside of a 49.2” x 49.2” x 13.5” high machining envelope.

- 1-BLM FiberOptic Laser, 2.5 KW resonator. Work piece – lengths from 60” to 315”, max 6” round and 4½” square tubular sections.

Lathe Cutting & Turning

- 1-Haas SL30 with 48” bar feed and live tooling. 14.5” x 34” (max capacity), 30” swing, 30 hp drive motor.

- 1-Mazak Nexus 250 MSY-II with 48” bar feed. Work piece – jaw chucking capacity of up to 14.75”, through chucking up to 3” on 35 HP main spindle, and through chucking up to 1.625” on 15 HP sub spindle.

- 1-Modern 3LD Lathe Type Tube cut off machine. Cuts 3/8” to 3” diameter round tubing. Equipped with automatic loading.

- 1-Modern 8LD Lathe Type Tube cut off machine. Cuts 1” to 8” diameter round tubing.

CNC Machining

- 2-Haas VF3 VMCs with pallet changers. 40”x 20”x 25”(xyz), 40-taper spindle, 20-hp drive motor.

- 1-Haas VF2 VMC, 30”x 16”x 20”(xyz), 40-taper spindle, 15-hp drive motor.

- 1-Haas VF7 VMC, 84”x 32”x 30”(xyz), 50-taper spindle, 30-hp drive motor.

- 2-Haas VF10 VMC, 120”x 32”x 30”(xyz), 50-taper spindle, 30-hp drive motor.

- 1-Haas VF6 VMC, 64”x 32”x 30”(xyz), 50-taper spindle, 30-hp drive motor.

- 1-Cincinnati MILACRON Maxim 500 HMC, w/ dual pallets and dual tombstones.

Drill-Saw & Beam-line Systems

- 1-Vernet Behringer FP400 Integrated Multi Spindle Drilling and Miter Sawing System. Drills and saw cuts up to 13” x 16” x 40 foot structural sections. Will drill holes in 3 planes simultaneously and cuts 45 degrees positive and 60 degrees negative.

- 1-Controlled Automation DRL-344, Multi-Spindle Drilling and Miter Sawing Integrated System. Drills and saw cuts up to 16” x 28” x 60 foot structural sections at plus/minus 45 degrees. Utilizes 3 independent spindles, each with a 24” x 16” X/Y envelop. I-beam drilling capacity is up to 44”.

Cold Saw Equipment

- 1- Eisle/Behringer PSU 450 CNC2 cold saw with 24’ raw length capacity. Cuts up to +/- 60 degrees and up to 6” round shapes and 6” x 4” rectangular shapes.

Bandsawing

- 1- HE&M H140 (Scissor Type) Horizontal Sawing System. Powered in-feed conveyor, powered discharge conveyor w/powered cross transfer arms. 20” round capacity, capable of gang cutting.

- 1-HE&M F130 (Double Column) Horizontal Sawing System. Powered in-feed conveyor, powered discharge conveyor w/powered cross transfer arms. Capacity of up to 25” round, capable of gang cutting.

- 3-HE&M Horizontal Bandsaws (Scissor Type) with hydraulic bar feeders for short parts.

- 1-HE&M Vertical VT125 Smart saw, Computer Controlled, with 48” feed stroke, powered head tilts to 45 degrees both directions.

- 1-HE&M Vertical VT130 Smartsaw, Computer Controlled, with 72” feed stroke, powered head tilts to 60 degrees both directions.

- 3- Additional Miter Cutting Saws (one is horizontal) that cut up to 6” rounds, 24” bar in-feed.

Bending Equipment

- 1-50 ton Hannifin break press capable of bends in bar, as well as tubing, up to 20° max.

- 1-Ercolina GB100 NC mandrel bender w/ 5-axis Semi-automatic control. Capacity from 1” to 4 ½” 10Gage tubing w/ up to 16” max. bend Radius / 1.5D. Up to 10’ part lengths.

- 1-Ercolina 030 3AXIS mandrel bender w/ Semi-automatic control. Capacity up to 3” Diameter w/ up to 8 ¾” max. bend Radius / 1.5D. Up to 5’ part lengths.

Secondary and Special Processing Available

- Heat Treating

- Plating

- Painting

- Tumble Deburring

- Metal Cleaning and Pickling

- Kan Ban

- Rust Prevention

- JIT Programs

- Kitting

For more information about our equipment and process, read about our history and values or reach out to us at 309.755.4601.