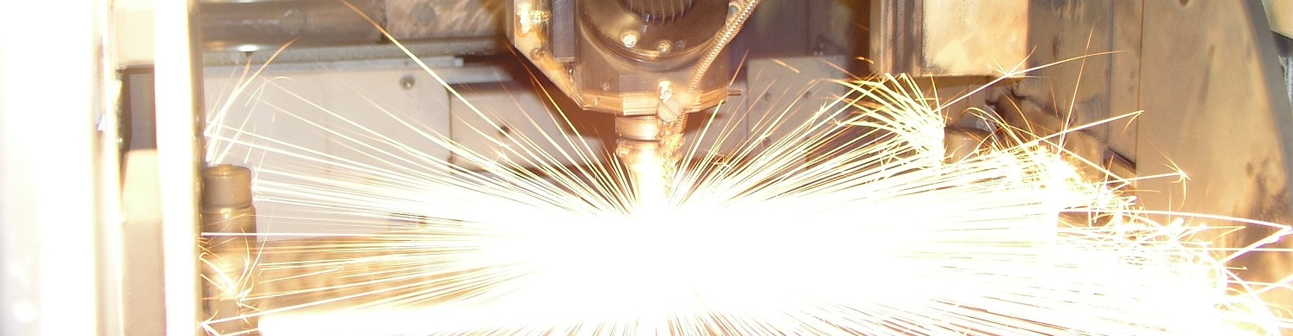

Our dedication to customer service and innovation at Production Cutting Services has led to a reputation for providing solutions to even the most complex manufacturing challenges. Our customer contacted us regarding a large scale project that included the fabrication of tool boxes designed for the repair of military vehicles in the field. To create the tool boxes most efficiently, the aluminum components needed to be cut using a 3D laser cutting system. Due to its reflective nature and thermal conductivity, aluminum presents some challenges in flat laser cutting, let alone 3D cutting processes. The customer had not been able to find anyone willing to take on the project when they contacted us.

We were able to develop proprietary cutting methods which feature a hybrid laser process, to not only accurately cut the aluminum parts, but meet the customer’s time constraints. The 6061-T6 aluminum parts were fabricated from tubing and angle shapes that varied in length from 6” to 72”. To reduce costs, parts were nested which maximized efficiency while still allowing us to meet tolerances of ±0.010”. This project was completed in the specified timeline of three months. For additional information about this custom aluminum laser cutting project, see the table below, or contact us directly.

Aluminum Tool Kit Parts Highlights

Project/Product Name

Aluminum Tool Kit Parts

Project/Product Description

Our customer received a very large order to manufacture a mobile toolbox that could easily be transported into the field to repair military vehicles. These toolboxes were to be constructed using aluminum components that needed to be laser cut. They could not find anyone with 3 D laser cutting capabilities that was able to cut aluminum sections. PCS, Inc stepped up to the plate on short notice.

Capabilities Applied/Processes

Primary: We developed a hybrid lasering process that was able to effectively cut 3 dimensional components out of aluminum structural sections.

Secondary: Provided cost savings by nesting various multiple parts out of the same raw material length using the nesting feature in our CAD System.

Equipment Used to Manufacture Part

Mazak FG150 Tube Laser.

Overall Part Dimensions

Various part lengths from 6” to 72”

Tightest Tolerances

+/- .010”

Material Used

6061-T6 Aluminum tubing and angle

In process testing / inspection performed

Faro Arm

Industry for Use

Government Contract for Military Equipment

Delivery / Turnaround Time

3 Months

Delivery Location

Midwest